F Series 0 Degree Worm Bevel Gear Reducer

F series gearheads are mainly used in large load output scenarios to ensure smoothness of motion, high torque output and high power density of the mechanism.

F Series 0 Degree Worm Bevel Gear Reducer

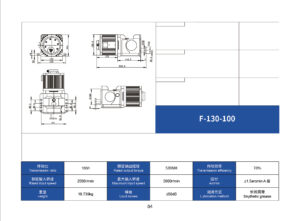

F-series 0-degree worm cone gear reducer

The transmission type of F series reducer is three-stage transmission, in which the core transmission technology is the ring surface envelope worm gear transmission technology independently developed by our company, which has the characteristics of high speed, large load, compact structure and high transmission efficiency.

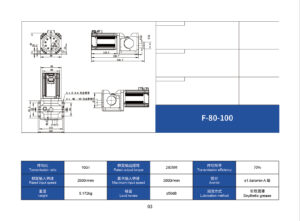

- Load capacity: rated torque 171.9-298NM, peak torque 515.7-893.9NM, static load torque 1203.3-2085.7NM.

- Center distance: standard 80mm/130mm, can be customized.

- Accuracy: Grade A ±1.5 arcmin / Grade B ±2 arcmin / Grade C ±3 arcmin, support customization

- Weight: 5.17-18.73kg 丨 Noise: ≤60db 丨 Efficiency: 70%

Product Advantage:

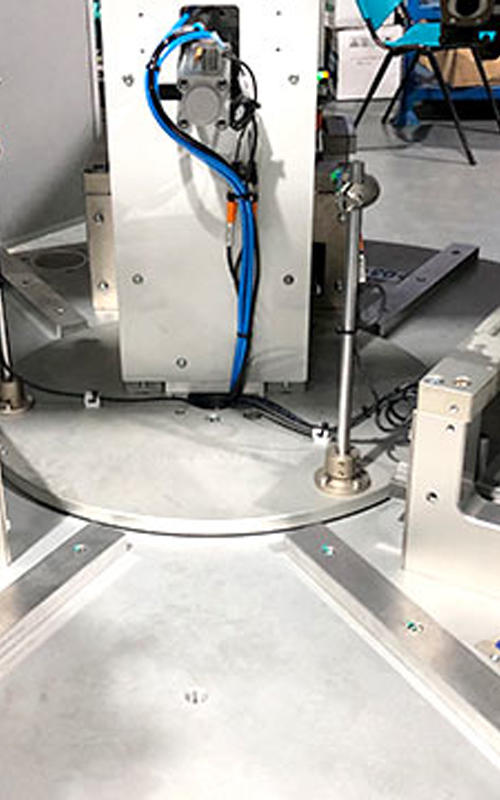

After 8 years of research and development, the original miniature ring surface envelope multi-tooth occlusion high-performance reducer is unique in the world's high-precision reducer field, and has won a number of national honors and a number of R & D patents. At present, Taoshi's miniature high-performance gearheads are widely used in a variety of high-tech fields such as high-precision industrial automation, industrial robots, humanoid robots, aerospace, military industry, medical devices and so on. With efficient and reliable transmission solutions, they provide strong support for various types of high-precision mechanical equipment.

- Smaller and lighter: 7075 aerospace-grade high-strength aluminum is used as the base material of the reducer, which significantly reduces the overall weight. Provides the best choice for the lightweight design of the robot. Let the equipment using our products fly higher, go farther, run faster and carry more. Greatly improves the range of the equipment.

- Higher precision: the precision is around ±1.5 arc minutes. High precision brings more accurate motion control.

- Stronger load-bearing capacity: Adoption of ring surface multi-tooth bite structure realizes a significant increase in load-bearing capacity. High-strength steel is used as the raw material. The tensile strength of this material reaches 1300 megabytes. It plays a vital role in increasing the load capacity, and the load capacity of our reducer is more than 3 times of the existing worm gear reducer in the market.

- Quieter: self-developed noise reduction technology, in the input speed of 3000 rpm measured noise is less than 47 dB, the use of our gearbox can make the equipment work very quietly.

Swipe right to view more images. Click on an image to view it larger.

Taoshi Intelligent Technology

Taoshi Intelligent Technology