An article to read: reducer just a few gears connected, why so expensive?

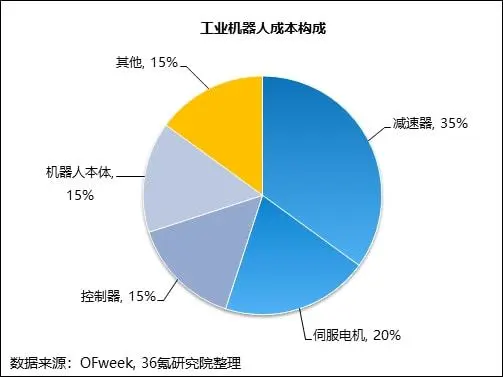

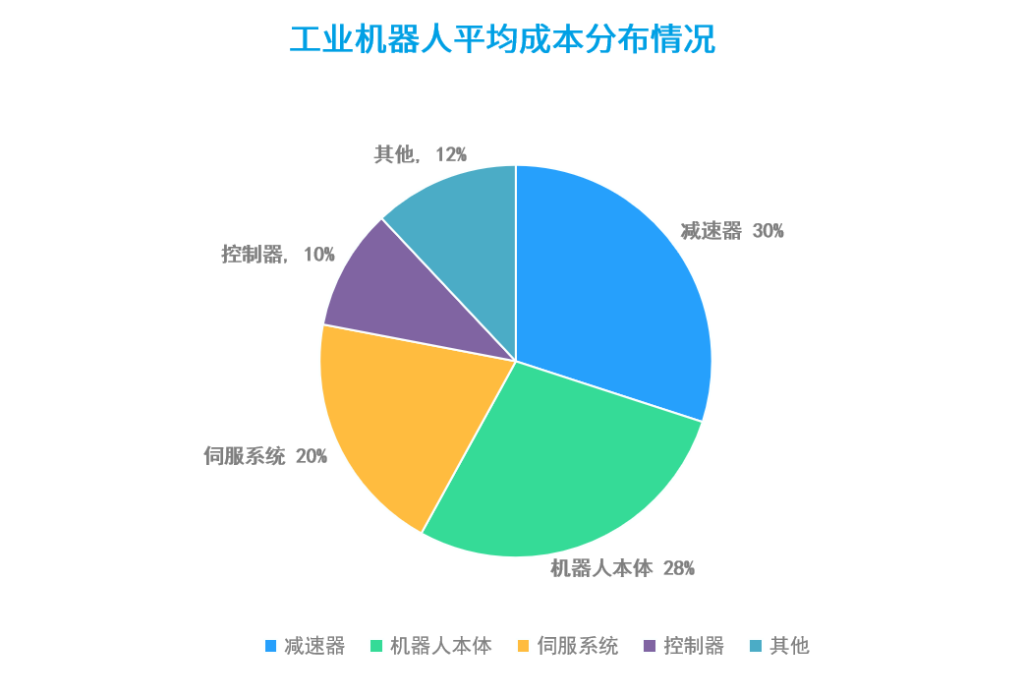

In some robot manufacturing cost statistics, always see some cost share analysis, no matter which report, the ultimate conclusion is that the cost of the reducer, at least accounted for more than 30%.

For example, according to OFweek statistics, in the industrial robot manufacturing costs, the cost of the gearbox reached 35%, followed by the robot body (except the gearbox), servo systems, controllers, accounting for 15%, 20% and 15% respectively.

According to the statistics of GuanRanReport.com, in the manufacturing cost of industrial robots, the cost of reducer reaches 30%, followed by the robot body (except reducer), servo system, controller, accounting for 28%, 20% and 10% respectively.

What is a speed reducer anyway? What does it do in a robot? And why is it so expensive? Find out today.

Why Reducers

In the movement of the robot, the servo motor is responsible for outputting power. However, without the cooperation of the speed reducer, the servo motor may vibrate or creep at low speeds, which will affect the performance and stability of the robot. Therefore, as one of the most critical components of the robot, the main function of the speed reducer is to reduce the speed and increase the torque, so as to improve the positioning accuracy of the robot when performing repetitive actions.

In the field of robotics, the main application is the precision reducer, which can be subdivided into RV reducer and harmonic reducer, as well as the ring surface envelope worm gear reducer that has just emerged in recent years. Each of the three has its own characteristics, complementing each other.

RV reducer

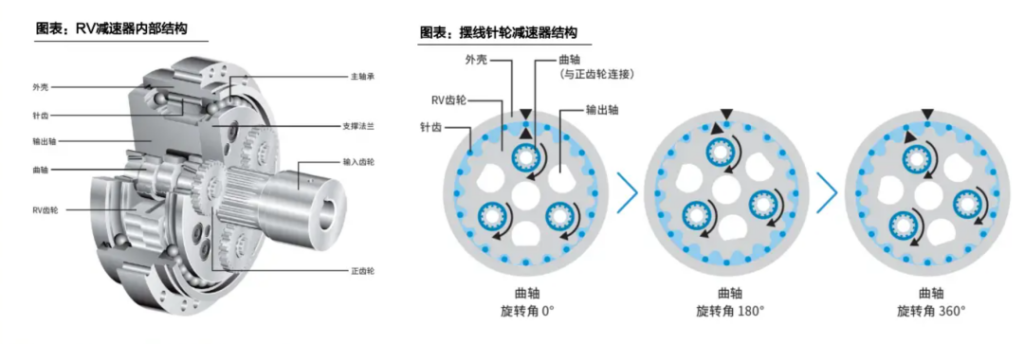

The RV reducer consists of a planetary gear reducer front stage and a cycloid pinwheel reducer rear stage. In terms of radial structure, it can be divided into three parts: the needle wheel layer, the RV gear layer and the arbor layer, which can be rotated independently.

The RV gearbox is equipped with a two-stage speed change function, which is mainly realized by the sun wheel and planetary wheel for spur gear change. When the planetary wheel drives the crankshaft to rotate, the eccentric break on the crankshaft will further drive the rotation of the RV gear.

RV reducers have good rigidity, strong shock resistance and stable transmission performance with high precision, making them suitable for medium and heavy load applications. Usually, these gearboxes are widely used in heavy-duty parts such as the base, arm and shoulder of multi-joint robots.

Harmonic reducer

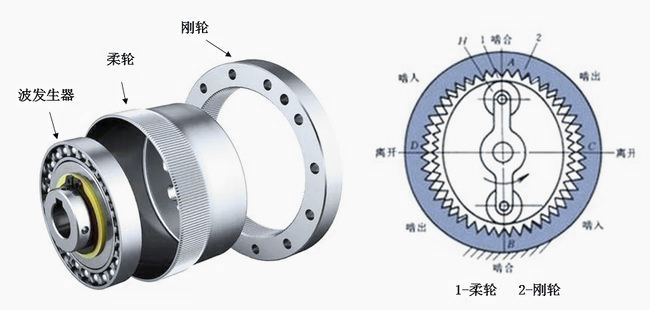

The harmonic reducer can be divided into three parts from outside to inside: steel wheel, flexible wheel and wave generator. The function of the wave generator is to make the flexible wheel produce controllable elastic deformation wave, so as to interact with the steel wheel to complete the transmission of motion and power.

Harmonic reducers are known for their small size and low number of components, and have the advantages of high precision and large transmission ratios, making them particularly suitable for small and low to medium load applications.

They are typically used in positions such as small arms, wrists and hands of robots for efficient power transfer.

Ring Envelope Worm Gear Reducer

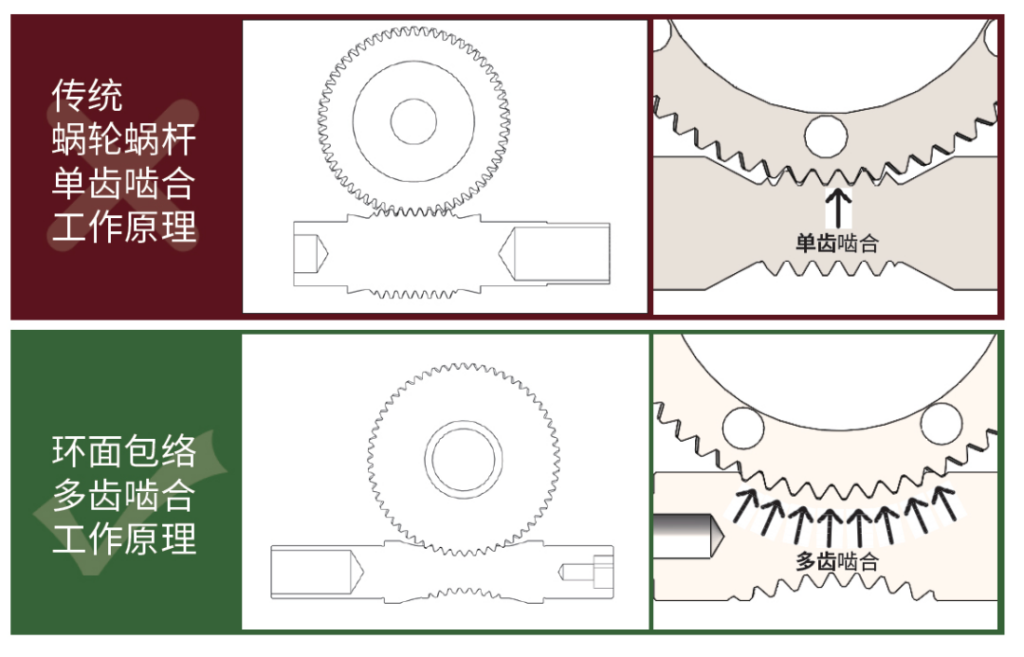

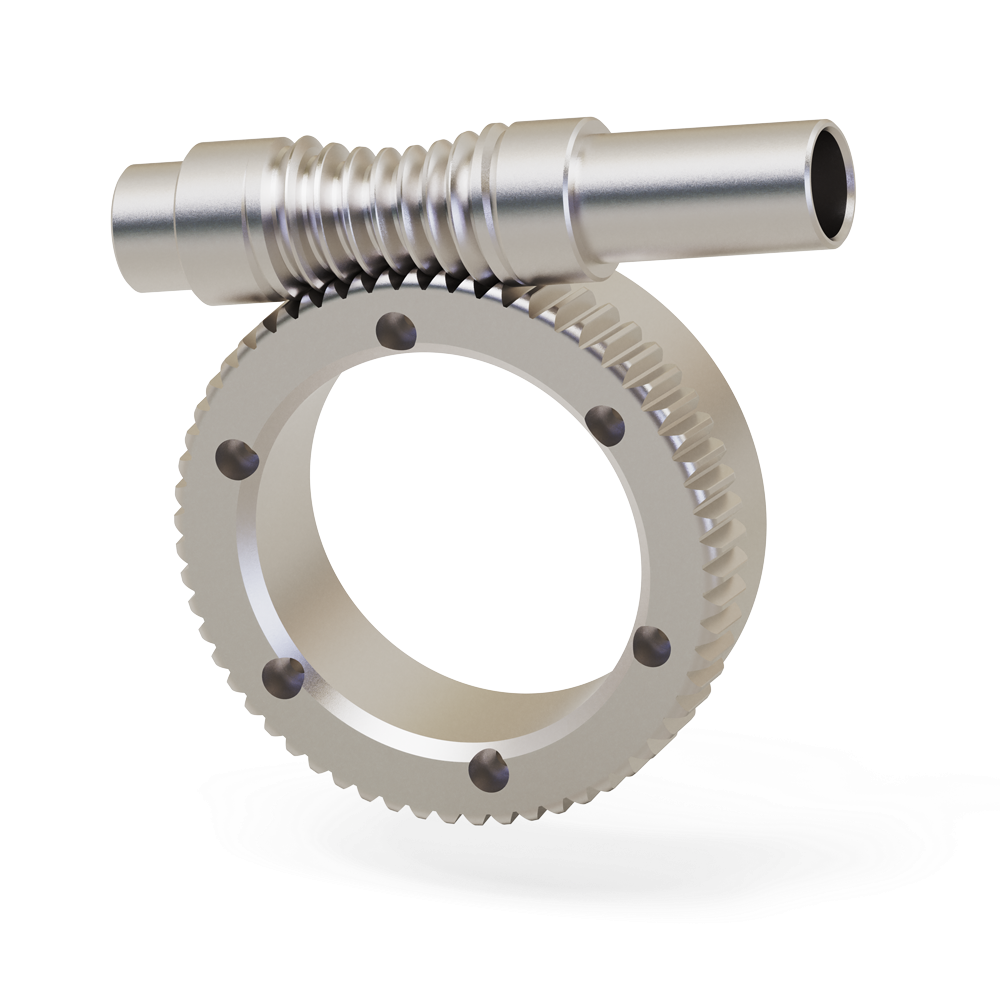

Worm gears with envelope originated in Germany and France at the end of the 19th century, initially due to the limitation of processing technology, the transmission efficiency is low. in the second half of the 20th century, with the advancement of technology, the transmission mode is gradually valued. in the 1960s, the German Fagor company developed a fully closed envelope worm gear, which promotes its industrial application.

In the 21st century, with the development of robotics, the technology has ushered in new opportunities. Prior to this, ring-enveloped worm gears were more commonly used in large or heavy industrial gearboxes. 2024, Dow Intelligence was the first to successfully develop a miniature ring-enveloped worm gearbox, which can be as small as the size of a knuckle, and its accuracy can still be maintained at less than 1 arc minute.

Currently, miniature annular envelope worm gear reducers are more often used at dexterous hand joints. to achieve greater finger freedom, precision and grip strength.

The higher cost of the reducer stems from two main sources:

First of all, the domestic research started late, resulting in the stability and service life of the reducer is relatively poor, and can not completely realize the replacement of imported products.

In the 1980s, China began to carry out theoretical and experimental research on RV speed reducer, while Japan and Germany had already launched a number of products with excellent performance. In addition, in the harmonic reducer research, China's start time is also a few years later than foreign countries.

The entry threshold of precision reducer is very high, mainly reflected in the long development cycle and large capital investment. High-end technical support is required in design, material selection, heat treatment, machining process, gears, bearings, seals, assembly, and testing of components and finished products.

In recent years, national brands have been making continuous progress in technology and have reached advanced levels in terms of precision.

In addition, the dominance of the market is held by a small number of Japanese companies, the speed reducer industry is still in a seller's market, with limited bargaining space. According to statistics, in the early years of Japan's Harmonic and Nabtesco in the global precision reducer market share of more than 70%, occupying an absolute leading position. In the harmonic speed reducer market, Harmonic Nano also with 36% share of the stable first.

In recent years, due to the rise of domestic brands, the international market share is gradually replaced by domestic. And the share is rapidly, can be said to be a leap forward.

The rise of national brands of industrial robots, but also to promote the process of domestic substitution of precision reducers. At present, China's industrial robot reducer industry, including RV reducer into a fast growth channel, the domestic RV reducer market localization rate is rapidly increasing. Overall, at present, China's precision reducer still exists in the barriers, domestic substitution is imperative.

Against the backdrop of counter-globalization, the United States has imposed a series of sanctions on Chinese high-tech enterprises, including controls on cutting-edge key technologies and restrictions on the cultivation of scientific and technological talents, all of which highlight the importance of achieving technological autonomy and control.

With the continuous breakthroughs in materials and process technology in the country, the call for domestic brands is growing. With the price advantage of domestic reducer, its market position will undoubtedly continue to improve, which also provides an opportunity for domestic enterprises to achieve breakthroughs in technology. Reducer is expected to become an important part of China's technological progress.

Taoshi Intelligent Technology

Taoshi Intelligent Technology